There are many areas of pork production that are detail oriented and require a plan. One area that is often neglected is how the animals are handled and cared for during loading and transportation. This process is performed at the end of the production cycle and the details can be overlooked. It is important to understand the animals’ needs, to take your time, observe the animals, and remove any distractions that can prevent a successful loading process.

1. Understanding the pig.

A handler cannot properly execute their job without understanding the pigs’ behavior and actions. It is critical for a handler to understand how a pig sees the world, how they use their senses, and how they react to situations.

2. Don’t rush.

It is simple to assume that if a handler pushes pigs with more force, that they will move faster, but many times this is not the case. A successful loading and handling experience is often determined by how comfortable pigs are when being moved. One way to minimize stress during loading is to move the pigs at a reasonable, walking pace. Animals that are being pressured too much often respond negatively and may reject movement.

3. Observe for stress.

There are physical indicators that all livestock handlers should be aware of that show signs of stress. Some of these indicators are open mouth breathing, red skin color, physical shaking, and abnormal vocalization. If these indicators are noticed, it is important to offer that animal a break before continuing the loading process. Becoming over stressed during loading and transportation can ultimately affect the meat quality.

4. Barn design distractions.

There will always be challenges during loading in both newly built and older construction barns. One of the best things that a livestock handler can do is observe for distractions by looking at things from the pigs’ level. Something as simple as a color change in the concrete can be a distraction for the pig. If you notice that pigs continue to pause in one location, there is a good chance a distraction is present. When the handler understands these distractions and adapts to overcome them the loading process will move more smoothly. If there is a distraction, it is critical for the handler to not push the animal with more force, but instead, let the animal recognize that the distraction is not a risk to them. If it is possible to remove a distraction, it is important to do so.

5. Recognize health status.

Before starting the loading process, it is important to observe the current health of the pigs and to be aware of recent health challenges. For example: if a group of pigs has recently been exposed to a respiratory challenge, these animals may have lower lung capacity which would make them more susceptible to the physical stress of being moved. In such cases, handlers should not push the animals too hard. Although it can be difficult to reschedule a transportation time, it is important to remember that animal health and safety is the top priority, and it may need to be considered to reschedule a load.

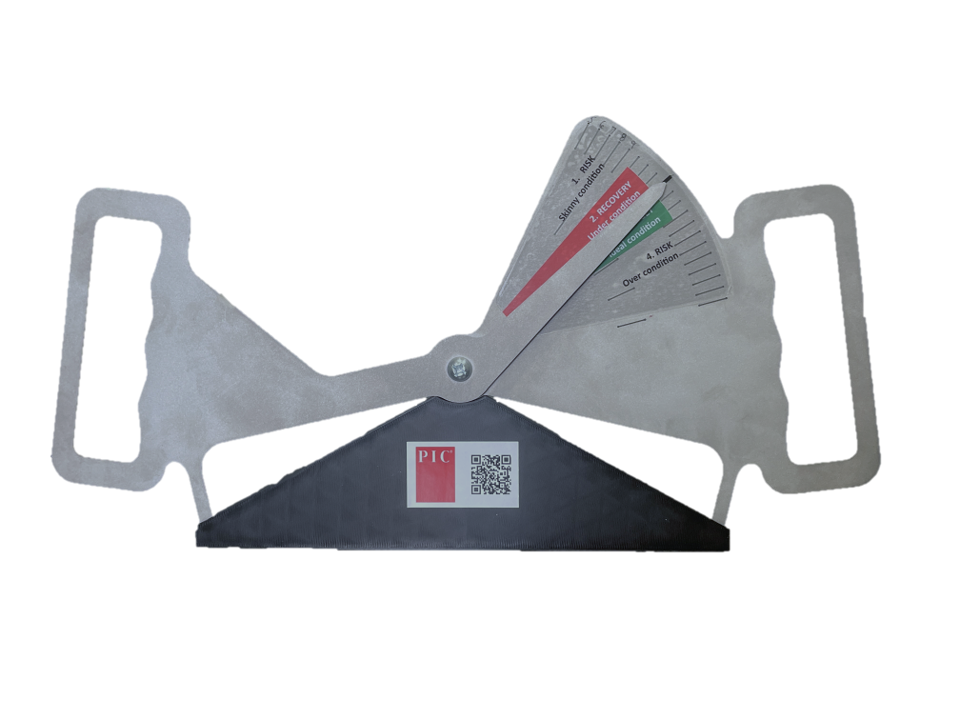

Loading is the last step in the production process and represents the culmination of months of labor and investment. Handling done with patience and care safeguards animal wellbeing resulting in a more quality and profitable product for both the producer and the consumer. Training should be offered to livestock handlers regularly. Every livestock handler and laborer should be reminded of the importance of their work and provided helpful tips to ensure a safe and successful loading process. There are tools and videos available on PIC.com that discuss the proper loading and handling techniques or reach out to your PIC representative for more information.